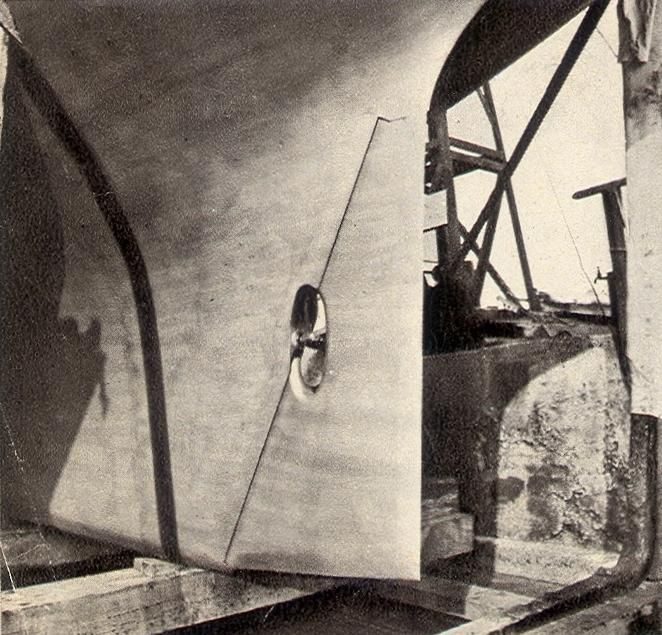

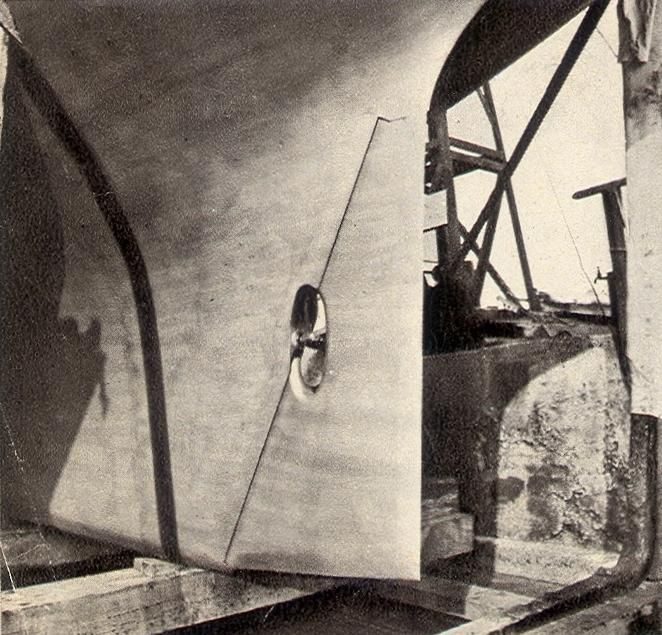

Here's a picture of a Sparkman and Steven rudder of the Constellation style from one of their ocean racers from the mid sixties. You can glean some interesting details!

Here's a picture of a Sparkman and Steven rudder of the Constellation style from one of their ocean racers from the mid sixties. You can glean some interesting details!

Pretty sharp.

.................................................. .................................................. .................................................. ..............

Was going to leave it at that.

But keep coming back to looking at that amazing rudder blade.

It's a translation, imco, right out of the test tank.

We can see the curves on the surface, as if the foil had just been tuned by a craftsman.

The techies did tilt the bottom up so it wouldn't crunch on the hard.

Years ago, looking up formulas for the foil, discovered that one shape rules them all.

One that all rudder shapers use. Or are definitely aware of. More or less.

A foil formula would work perfectly on a rectangular blade, which they aren't hardly ever.

So the rudder shaper is right back with his bronze & mahogany buddies......

he has to shape by EYE. Because the 'formula' infinitely changes on an non-rectangle blade.

Imco, getting the 12meter ready to win, designers would constantly, up to the race, be twiddling with the rudder.

Because it is an unknown, you have to work toward perfection - which we all know is unattainable......but let's keep trying.

Believe ledgendary surfboard shapers haven't got no stinkun formula: it's by eye. intuition, and feel.

Stick THAT in yor blinkin computer.

Do hold that shaping a rudder is in the realm of art.

Do hold that Alberg designed a foil shaped underbody into the Ariel/Commander, including the leading edge bulb entry.

So having the rudder profile as a foil is your call. It can be argued that board rudders with rounded trailing ends sailed just fine for 50 years.

On my composite constellate there will be a conservative 0012 aft foil profile leading to a fairly narrow blunt trailing edge with hard corners, no round.

Also will fill out the vertical profile to just inside the width of the keel. It's problematic but still the idea as to reduce drag and minimize eddys. It's also a more stable and more natural profile. One side of a board rudder is always cupped, imho.

Will stay within the aft two thirds of the NACA airfoil ordinates. No bulge, a sort of pumped up straight line.

google Keel hung rudders? http://www.boatdesign.net/forums/sai...ers-22016.html

Unlikely, but if your BS1088Meranti cups at all, Cut the opposing shapes so that the cupped sides get glued together. Might be kidding but don't think so!

.................................................. .................................................. .................................................. .................

Art imitates Nature, and necessity is the mother of invention. Richard Franck

Last edited by ebb; 04-15-2013 at 02:29 PM.

Well, I had to buy another sheet of BS1088 plywood for the rudder because the new shape was bigger than I had material to make if from. So I decided this weekend to use the first half piece I had previously made to make a template for the new pieces when my plywood gets here. I got the top of the rudder a little too close to the bottom of the hull because I still need to wrap everything in many layers of fiberglass so I will need to cut that down some to make my template accurate.

The bottom of this template slopes uphill at 13 degrees in addition to the lowest point being 2" above the bottom of the keel. That should keep the bottom out of the mud.

The other thing I did this weekend was build a jig so I could install the wood rails that the motor will mount to. I made and installed the rails and now I need to glass them in. Pictures below.

Last edited by Commander 147; 04-15-2013 at 10:51 AM.

JERRY CARPENTER - C147

A man can succeed at almost anything for which he has unlimited enthusiam.

Hey Jerry, sure looks good. One thing to remember when test fitting:

You need around a half inch gap between the hull and the top of the rudder so you can lift it high enough to get it into the shoe. You can just make a notch around the shaft and turn it to one side when installing. I made this mistak when I built my first Ensign rudder and had to hack into my masterpiece at the boat yard cause I was installing and launching at the same time. I could not test fit without lifting the boat from the trailer.

Mike

C227

That is a VERY good thing to point out. And if not for shear dumb luck I could have easily missed that point. But the previous owner had a new rudder built for Destiny and they did not do a good job of allowing for that. So when I finally was able to get Destiny on a lift and remove the old rudder it did not want to come off for that very reason. That fact made me quite aware of the issue so I allowed for it this go around. Here is a picture where I was test fitting the prop location where you can see much better the notch that did not show up well in the previous picture.HTML Code:One thing to remember when test fitting: You need around a half inch gap between the hull and the top of the rudder so you can lift it high enough to get it into the shoe.

Also I found this article in Good Old Boat and used it to try and tweek the prop location. This is what I was able to work out which is as close as I could come to the ratios they recommend.

JERRY CARPENTER - C147

A man can succeed at almost anything for which he has unlimited enthusiam.

looking great! your craftsmanship is a continual inspiration. I have many questions, however today I have two, maybe three, as they coincide with my own rebuild on A97.

1. how have you calibrated the shaft alignment athwartship? Since i deleted any existence of the previous engine mount i have little to align against. The only thing is the cockpit bulkhead, a theoretical perpendicular, however the shaft does not actually exit the boat parallel to the centerline. Or does it?

2. three blade prop for electric conversion? for regenerative efficiency? what is the spec? I was thinking of an Atomic4 prop (http://www.atomic4.com/propeller.html) seemed like a reasonable price for a three bladed prop that would fit our aperture.

and unrelated.

3. I sent an PM about your masthead setup. would your fabricator be interested in making another? I ask, as it might be quicker and easier than trying to get my busy fabricator to sit down and make it happen.

ok, one more!

4. I have spent days trying to get the Pearson Ariel cast aluminum mast base out of the bottom of the extrusion to no avail... the PO had snapped the screws (x4) off years ago so its on there. Ive heated, smacked, chisled, used penetrants... but there is just no 'purchase' to pry or lever the base cap off, any suggestions?

I saw your post this morning but I am on my way out to see a customer in Orlando this morning and can't take time right now to give your questions the response they deserve. Hopefully tonight I can. In the meantime I did not get a PM from you. So you might want to try that again.

JERRY CARPENTER - C147

A man can succeed at almost anything for which he has unlimited enthusiam.

Carbonsoup

In response to your question #1.. I would not use a bulkhead installed in a Pearson boat from our era to align anything. I can tell you none of the bulkheads in my boat were perpendicular to the fore and aft centerline. They were as set buy the TLAR (that looks about right) method. And yes the shaft should be dead on the boats centerline. The way you have redone your boats interior would make it impossible to use the method I did (which is to streatch a mason's string tightly from the point of the bow to the point where the shaft exits the boat) to align the shaft on the centerline but you could probably figure out a suitable alternate method like determining the centerline of your cabin bulkhead and stretching a string line from there to the exit point of the shaft.

Question #2.. The reason I went with the prop I did (which is an 11 x 11) reasons. First I determined the diameter that would best fit the aperature in the keel and rudder based on the ratios from that Good Old boat article I posted previously. Then I worked closely with Scott McMillian from Electric Yacht to determine what would be the best pitch for the 2:1 reduction we were using for my electric motor and the output power it developed at the shaft.

As far as regeneration I'm not holding a lot of hope for that even though my system will work that way. And the 3-blade prop will do a better job for regeneration than a 2-blade one would do. But from people that have done systems like this they don't feel they get a lot of benefit from it.

Question #3.. Yes the fabricator I used would be happy to make another mast head assembly. Are you planning on following Mike's advise (C227) about lowering the forward sheeve on the assembly? If so it would take a bit of time to rework the drawing. I can help you get it ordered with the fabricator I used. Shoot me an e-mail so we can discuss. My e-mail address is gocarpen at tampabay dot rr dot com.

Question #4.. When I was removing my mast base I accidentally snapped off a couple of the screws also. You will never get the base off if you don't completely drill out those screws. When I did it I ended up with buggered up holes in the bottom of the mast that I had a welder plug at the same time he plugged all of the other no longer needed holes in the mast. Once I got the broken screws out completely the base came off pretty easily. Before that there was NO moving it.

Hope this helps.

JERRY CARPENTER - C147

A man can succeed at almost anything for which he has unlimited enthusiam.

This afternoon I got the motor shaft lined up with the prop shaft and connected the two. Everything appears to be where it belongs with the prop and everything else so now I can glass in the shaft log.

JERRY CARPENTER - C147

A man can succeed at almost anything for which he has unlimited enthusiam.

Now that I am getting near the end of the labor intensive work I am approaching the cost intensive portions of this restore. Today I will place the order for the new hardware which I have listed below with Rigging Only. I bought my standing rigging from them and they are VERY competitive in pricing and do what they say they will . Good people to work with. In addition to that $5,600.00 worth of hardware I am still looking at a $5,000.00 paint job, a $7,000.00 suite of new sails and $2,800.00 worth of batteries to power the electric inboard. And none of that includes any of the many more misc. items I will need before I finish. Sure am glad I do not intend to ever sell Destiny. And I hope the grandkids appreciate the boat they will have some day. :-)

JERRY CARPENTER - C147

A man can succeed at almost anything for which he has unlimited enthusiam.

Sounds like you've got your mind right... You'll never be able to sell it for more than half what you've got into it. And all your labor? HA!

You're building what you want for you. It's a labor of love all the way.

We're not alone in this however. I was at a car show and saw a T bucket for sale for $12,000. It was a work of art. He had over $30,000. Into it and every weekend for the last 5 years.

Thanks for posting this information Jerry. I am in the market for a travelor and a few other items. Your list has pointed me in the right direction regarding source and model numbers. I had my bottom soda blasted a few weeks ago. Hoping to sand, fill and sand some more this weekend and apply interlux 2000E next weekend, weather depending.

Have I said lately how much I dislike working with epoxy down in the bowels of Destiny??????????

I have only a few smallish projects left for epoxy work on the inside of the boat and I can't wait until that list reads zero. Especially since we have returned to full fledged summer weather here in Florida which means 95 degrees and 95% humidity. These are our cabin fever months.

Of the things I have accomplished since my last post, the one I enjoyed doing the most was building the new AC electric panel enclosure. Picture below.

Also I reinforced the bottom of the cockpit floor because it was so spongy even where the core is good. And while doing that I redid the rudder tube where it goes through the cockpit floor. The tube and the cockpit floor were not bonded at all prior to my reworking it. A picture of the cockpit floor reinforcement is below.

And then I glassed in the prop shaft log. I probably over killed that but I guess it's better than under killing it. ;-) Picture below.

JERRY CARPENTER - C147

A man can succeed at almost anything for which he has unlimited enthusiam.

wow. regarding rigging prices, i would seriously consider Garhauer marine hardware. Im not trying be an internet ass, I am sure you have seen their stuff before however, I was at the Oakland boat show a couple years back when I was ogling other hardware and ran into the Garhauer booth and I was really impressed with the level of durability, fit and finish... I say this as I looked over your spreadsheet and saw some prices that made me wretch... for example, the low lead cars from Schaefer are 312 bux, yikes. The low lead cars that I have been looking at from Garhauer are 100 for the pair and I prefer the solid SS look and feel of Garhauer over the plastic Harken stuff. Now, I say this with the caveat that I am not racing, if that were the case I might reconsider as weight might make a difference... but even then...

Last fall, Garhauer had a sale and I bought a new main traveler (MT-2) for 200 bux. I admit, the bling makes me smile, but I dont feel weird about it cuz I only spent 200, not 500, or more.

Last edited by carbonsoup; 06-13-2013 at 08:00 PM.

I can second the Garhauer post. Take a look at their hardware:

http://garhauermarine.com/

They've got a 20% off sale going on some stuff until June 30.