Had plug out when i tried to start it. Didn't put in enough oil for it to squirt out plug hole. Motor turns, but not freely/fast enough to start. MM oil is good idea.

Had plug out when i tried to start it. Didn't put in enough oil for it to squirt out plug hole. Motor turns, but not freely/fast enough to start. MM oil is good idea.

also do not forget to clean the oil off of the spark plug. The oil will not allow the motor to fire if left on the insulator.

I just purchased a tohatsu 20" sailmaster. Fingers crossed! Ill report back when I have used it a few times. It seemed to be the best deal, and it will charge batteries while running. I see the 20" version of the sailmaster was not offered in the nissan badge. If they are the same engine, I wonder why it is available in one brand and not the other?

To those that already own this engine, how good is the charging system using basic necessities? Example, vhf, gps, led cabin lights, anchor light.

Dulce et Decorum Est

> To those that already own this engine, how good is the charging system using basic necessities? Example, vhf, gps, led cabin lights, anchor light.Beware: the output is unregulated half-wave (uni-polarity) AC. If you look at the output of a typical outboard generator on an oscilloscope, it's half wave pulses that peak around 18 volts. Unless that model is more sophisticated than most - the generator is intended to power incandescent running lights on a skiff that's underway at night - not sensitive electronics like radios and GPS receivers. Incandescent bulbs are rather insensitive to the non-uniform current, and their filaments stay hot when the voltage dips to zero for tens of milliseconds at a time (which is why they work as well on AC as DC current).

LED lights that are rated to handle 24 volts or more (most these days have regulators to allow dual 12/24 volt power) will probably tolerate the spiky voltage, but you won't like the flicker you'll get at low RPMs, without a battery to smooth the voltage. For powering ONLY LED lights (not electronics) you could use an electrolytic capacitor in place of a battery to stop the flickering, but to be effective at low RPMs, it would have to be huge.

While it can be used for short duration and occasional charging of a battery that is large enough to absorb and smooth out the pulses (multiply the generator's rated output current by 10 - you need a battery of at least that many amp hours), be VERY careful that no situation can ever exist where the battery becomes disconnected so it is no longer regulating the voltage spikes and the generator is powering sensitive electronic systems directly. If it ever does - you may have a very expensive smoke generator, or at least a mysterious source of failing electronics. Transistors don't like transient voltage spikes. Also, you will only get the rated output current when the engine is running at top RPM (in neutral) and making a sound that will likely drive you nuts.

I'd also suggest installing a fuse at the battery terminal rated for the full output current of the generator on the lead from the generator. The generator should have a fuse inside the engine, but if the wiring becomes shorted along the run downstream between that fuse and the battery, there's nothing to limit the battery output current.

If you want to verify what I'm saying and you don't have an oscilloscope: get an 8 ohm speaker you don't care about ruining, connect a 100 ohm 1 watt resistor in series with either speaker terminal (to limit the current), and then connect the generator output to the speaker through the series resistor. Start the engine and listen. If it's DC, the speaker cone will just move one way or the other once and not produce any sound. Instead, what you'll probably hear will sound like a playing card running through the pokes of a bicycle, with the pitch varying with engine RPM.

Last edited by pbryant; 11-24-2012 at 12:25 PM.

Have the same motor in Louise Michel. Took out an old Gray Marine inboard that came with boat. What a nasty job that was. Haven't regretted it once. Have about a thousand hours on the engine, including an eight month trip to Bahamas -Norfolk to Miami, down the ICW, eight hours a day, day after day, that little motor ran like a top.

I have the charging system but haven't used it. Instead we use a 80W solar panel mounted on a raised stern pulpit, with a 15A contoller and two 90AH deep cycle batteries. Powers cabin lights [ some incandescent, some led], running lights when needed, VHF [not always on], GPS. Run laptop, battery chargers [AA, cordless drill etc] and FM radio via a small inverter. Anchor light is a rechargeable lantern hung on boom.

Doubt you'd be able to power all the items you list, about what I have, from engine charger without running it just to recharge batteries but you have to do the math...add up all the items times hours of use, figure in the formulas for inefficiencies, rate of discharge etc.

So what is the unregulated charger good for? I could get a charge controller or just use the system as an occasional battery charger. I could isolate 2 batteries with a solenoid that is only engaged to the house system when I want it to be while monitoring the charge. I don't plan on motoring much, it is a sailboat. I still feel I did well even if I don't ever if rarely use the charge feature, because I got the high thrust prop and that has made up or broke even in cost. What would you do with the charging system? I can not find out how much oil goes in this thing anywhere. The owners manual covers what type but not the amount. How much oil goes in the engine? How much and what kind of oil goes in the lower end? Its not even stamped or written on the engine anywhere.

Dulce et Decorum Est

Is there any reason not to install the (semi permanent) steering lock on this motor? As mentioned in my intro I am new to sailing. Last week I was out practicing docking when the motor slipped loose thus causing a few hair raising moments for me at my new marina. With the exception of losing the ability to use it for maneuvering tight quarters I think it would be fine. And in the remote chance of losing the rudder it does unbolt easy enough. I used the search function and did not turn up anything salient to my inquiry. Thanks.

I installed a strut from the lazarette wall to the front of the motor. The strut bolted to the motor handle with a wing nut so it could be quickly detached [in close quarters, especially going in reverse, we 'steered, by turning the motor]. The other end of the strut was simply clamped to a flange to allow for adjustments.

PS.The wing bolt on the back of the motor is there to adjust friction not clamp the motor in place.

The only practical way to steer while moving astern is to steer with the engine. The ability to spin the engine around in its port to assist in steering is a great advantage over the inboard version of Ariels. None of the Alberg designed boats were designed to show finesse and grace while backing up. And while the Ariel - with her modified full keel - has a tighter turning radius than a battle ship while moving forward; in the close quarters of a marina, you may need to hasten her turns by twisting the engine. You want some resistance/friction to the engine's uncommanded turning in the port, but not so much friction that you can't turn the engine at all. When the eventuality arises that you need a really tight turn, it will be an emergency, and any delays may result in a collision.

Ariels have a great deal of yaw stability, i.e., resistance to turning. That is a wonderful feature in sharp ocean swells where they track like a train on rails, but not so good in a tight marina.

The biggest problem, at least with my Nissan Sailpro, is it's tilting while underway. The long shaft dragging in the water causes it to tilt way back, and to such an extent that the pull-to-start handle is buried out of reach, you can't shift into reverse gear from neutral, and the shaft angle contributes to shipping water into the boat. I found no way to correct this -- until I resorted to installing a piece of anchor chain across the shaft to prevent the behavior. Apparently Nissan thinks an engine that's marketed for use on sailboats still needs to tilt freely to prevent damage from a grounding -- as if it were installed on a dingie. The tilt "feature" is worthless on an Ariel, and I presume all other sailboats where the propeller isn't lower in the water than the boat's keel.

The only situation I can envision where the tilt feature would be helpful is when running over a crab pot line where it slips under the keel and then gets stuck on the forward surface of the engine shaft. And the engine still can't tilt back far enough to free the line. I have a knife on a pole ready for that situation. It's also good for fending off pirates ;-)

Last edited by pbryant; 04-12-2014 at 10:38 AM.

Rather than a knife on a pole - I suggest using a boathook and a knife from your pocket. That way we can re-tie the crabpot lines back together after freeing ourselves while not screwing the owner out of making a living or doom generations of crabs to a useless death.

PHM

-------

Pulling the crab pot line aboard, up through my engine port, in ocean swells, or dangling myself in swells over the stern while trying to snag the line with a boat hook, while the crab pot acts as an anchor (requiring hauling the boat astern to the crab pot - provided the pot doesn't haul me overboard first) can be a difficult and dangerous process. And no, I am not going to try to back down on a line astern with the engine in ocean swells - while hauling it aboard through the engine port just inches away from my prop. As much as I might like fishermen, I'm not going to try to haul the line around to the bow or risk falling overboard or an entanglement with my prop.

I don't mind saving the fisherman's pot if I can do so without risking my life. Provided the crab pot isn't placed in a marked navigation channel, in which case it's as much a vessel trap as it is a crab trap. I have seen many of those around Half Moon Bay. Some clearly abandoned with what looks like years of overgrowth on the floats, meaning there's nothing but crab skeletons inside the traps. Archaeologists will be studying those non-biodegradable floats and line in a thousand years. There should be a maximum amount of time pots can be left in place, after which, people should be encouraged to pull up the abandoned traps, and if they are stuck on the bottom (which is probably why they were abandoned) to cut the lines. Maybe a bounty on cut and turned in abandoned traps and floats would help clean up the mess. By the way, the California Fish and Game code states that crab pots not serviced, or placed in a navigation channel, are a public nuisance.

The environmental laws prohibit discarding plastic in the ocean. Some of those (plastic) floats and (plastic) lines are clearly discarded. And the people who abandon them without removing as much of them as they can (at least the floats) - aren't fishing - they are littering.

As I write this, recreational season for Dungeness crab doesn't start until Nov. 1st, and commercial season doesn't start until Nov. 15th. There shouldn't be any crab pots anywhere. But take a cruise around Half Moon Bay, and you'll find enough of out-of-season pots to turn your cruise into a slalom course.

Maybe someday the technology and requirements will have lights attached to the floats so they can be seen at night. Meanwhile, there is nothing preventing fishermen from applying retroreflective tape to the floats - if they really care about vessels avoiding them at night.

Last edited by pbryant; 02-11-2016 at 05:18 PM.

I have a Nissan 6 HP outboard (model NSF6). There are two annoyances that I resolved.

1) The Ariel's engine mount, a block of wood, allows the engine to slide up that block and pop off it entirely. It is very unpleasant to have the engine flopping around loose under power. In reverse gear, I’ve had it fly up and nearly slap me in the face. Even though there are deep divots that have been worn into the wood by the mounting clamps, to prevent movement, the clamps still have to be torqued down so hard using tools to prevent slippage, that they eventually break. And swells pushing upward against the engine lower shaft eventually loosen the clamps and walk the engine off the wooden block regardless of how severely the clamps are tightened.

I solved this problem by installing a stainless steel bar across the top of the engine port mount. Carefully measured to allow the round clamp pads just enough clearance to pass under the bar when the engine is installed, the bar retains the engine while allowing only very slight movement, and I can install the engine and remove it (which I do after each sail) without torquing the mounts excessively. When the clamps inevitably loosen after a long sail, I only have to reach in and give the clamps another twist. The engine stays put.

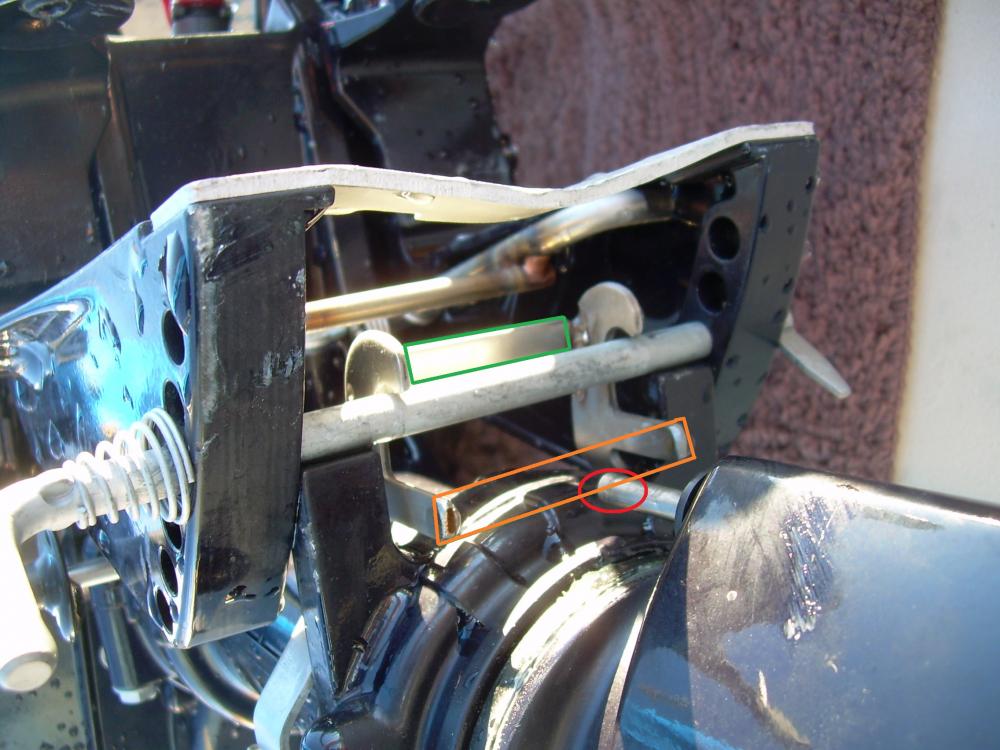

2) The Nissan has a “feature” that allows the lower shaft to tilt back when the engine is in forward gear. Referring to the attached drawing, the reverse lock arm (32) engages the thrust rod (12), but only in reverse and neutral gears.

In forward gear, the engine is allowed to tilt back freely. This is a useful feature on a skiff that prevents prop damage when the skiff is run up on a beach, referred to in marketing material as a "Shallow Water Drive." But the free-tilting behavior is completely useless on a vessel where the prop is higher than the keel and will never strike the ground (you’d have to back into something to strike the prop). Plus, the tilt range in the Ariel is too limited to be of any value – only a few degrees before the engine cowl slams into the forward wall of the engine compartment (damaging the cowl).

This free-tilting behavior becomes a major annoyance when you discover that, after raising sail, your speed through the water causes the engine to tilt and force the cowl (engine cover) against the compartment wall when you select idle thrust while in forward gear, and that there is no practical way to restore the engine to vertical besides stopping the boat.

When docking, it becomes a major hazard when you try to go repeatedly from forward to reverse. If you have any forward speed, the engine will never return to a vertical position because the lower shaft is dragging through the water. As you throttle down in forward to switch gears, the engine will tilt aft. When you select reverse, the reverse lock arm can't engage because of the aft tilt, and the engine consequently slams and see-saws back and forth in the engine port.

The kind folks at Svedsen’s solved this problem for me. Referring to the attached photo, they removed the semi-circular swashplate (area marked in orange) so the push rod end (circled in red) cannot engage the reverse lock arm to move it out of the locked position. They then welded a cross piece (marked in green) to the top of the reverse lock arm. Alex in the chandlery came up with this solution. The engine now remains locked in the vertical position in all gears. The modification can be reversed by installing an original reverse lock arm.

Last edited by pbryant; 11-17-2014 at 03:14 PM.

And with a team of Navy divers, I might have accomplished that. If you watch my video (link below), you'll see my predicament. There was:

- At least 100 pounds of tension on the line trying to pull my engine down through the engine port into the sea. The swells were adding shock loads that were way beyond anyone's ability to pull the engine up out of the port. I would have broken my strongest gear trying to haul the engine up against the shock loads. The crab pot float was jammed between the anti-cavitation plate and the prop.

- Ocean swells were boarding my stern. I was effectively "anchored by the stern in swells." Boats sink that way from waves boarding astern.

- I had no way to reach the line, or even see it.

- The line went vertically down into the water, so it could not be accessed from any angle over either side or the transom.

I'd been bobbing around for over an hour with swells boarding my stern, pooping the cockpit, while trying every other method to access the line, including keel-hauling a line from the bow to grab the line (the swells just forced the line forward of the stern).

It was now sunset. With daylight nearly gone, what would you have done?

And for the record, I don't believe I cut the line, but instead impaled the float with my knife and forced it to slip under the engine shaft, as the video shows. Since there were two floats on the line, the fisherman should still have been able to retrieve it. Not that it would be worth very much, after I dragged it half a mile across the bottom.

Crab season ends June 30th. Until then, I'm going to add a tree trimmer (http://www.harborfreight.com/media/c...mage_17978.jpg) to my gear. This happened in very mild swell conditions - 3 to 4 foot swells. If it had been the usual 8 foot swells that I sail in, I could have lost my boat from waves boarding astern. I've spent $600 on LED lights placed on my bow to spot crab pots at night. I've done my part. But it's a mine field out there! And I see very few crab pot floats with reflective tape on them. Apparently the fishermen don't care enough about losing pots to add $1 worth of reflective tape. I do care about losing my boat and my life.

https://youtu.be/Nj8oXKjRZxE

Last edited by pbryant; 05-22-2015 at 09:24 AM.

The friction on my nissan o/b never really worked well... I eliminated the issue completely by installing a couple of tiny dinghy cam cleats with fairleads on small blocks of teak and I then epoxied this onto the bulkhead - One each on each side of the motor. I ran small 1/8" or 3/16" lines with a stopper knot through the holes on the o/b 'handle' and into these cams via the fairlead. It worked like a charm...

This Secured the motor straight as an arrow, but it could also be released completely in a fraction of a second when needed. The lines came off tthe motor for starage right away as they were only help by the stopper knot - I highly recomment this route.

I'll look for some pictures to post... I'm pretty sure I took some at some point... I must have!

Rico: Photos, photos, please . . .