A place to check is a Cape Dory site.

Might say that Alberg designed little ships with the smell of Marblehead salt water in his studio.

So he would no doubt have small boat sailors in mind.

CAPEDORY25D is imco pretty much his bringing the Ariel into the future. I believe the boat is

from 1978. This design, a slightly more matronly version of the Ariel is nearly the same weight,

length, and width as the Ariel.

He designed it with the constellation style rudder. Which incidently appears in dashed lines on a lines drawing (Manual pg 144) of the Ariel.

Document is not signed - it is dated: November 1961 - from the same Carl A. Alberg studio in Marblehead....... 1961 ! !

I don't have any CapeDory lines to do closeup comparisons.

But Alberg, 15 years later, did draw his day sailor/racer CAPEDORY TYPHOON with the round trailing edge of wooden boat heritage. I don't know if the daysailor's rudder is the more simple plank design.

Notable, but only looking at computer images, is that the bottom of the Typhoon rudder seems to be drawn below the keel line. Not rounded up as quickly as the A/C. The rounded shapes are different.

It is often pointed out that when you ground on mud or sand with a keelhung rudder, that an ear shape

design to the appendage might be more likely to be freed to help manuever the vessel - and protect the blade.

So depending on your cruising ground, you can choose your rudder if, as Ben says, there is no discernable difference in speed or maneuverablity.

It evidently did make a difference to Olin on the 1964 Constellation (Sparkman/Stephens) when they first raced it out there.*

Given the dates, I'm assuming Olin called up Carl and asked him what he would do to get a 12meter to go faster.

By the numbers, it's obvious we must credit Carl with the invention of the constellation rudder. But of course!

While the rounded rudder looks like a dragger on the '70's CapeDory Typhoon, it looks like the straight bottom rudders on family CapeDories are canted UP slightly form the line of the keel bottom. The trailing corner shows no rounding on CD's, while the dashed Ariel has considerable.

There is a lot of airfoil (lift) designing and experimentation lavished on modern rudders.

I haven't visited CapeDory sites much - but I would assume the '70's rudders are a fiberglass composite of some sort and are foiled.

I'm persuaded that streamlining the rudder into a constellation aspect at least on paper will

add something to the efficiency of the marvelous streamlining of the Ariel/Commander hull. Who knows how much.?

With similar blade area the foil shaped flat bottom constellation couldn't be less speedy than its predecessor.

I wonder, however, that the rudder surface being in effect LOWER with the constellation that

more control over the boat going downwind is experienced?

Arguement being that lower down there is less water turmoil created by water dragging along the hull.

Racers are minmalist. Guess that water surface is right on the designer's edge. A day racer interested in the fastest straight lines

might calculate what the designed surface areas of the two rudders are.

We have both to compare on the A/C - which is INCREDIBLY UNIQUE.

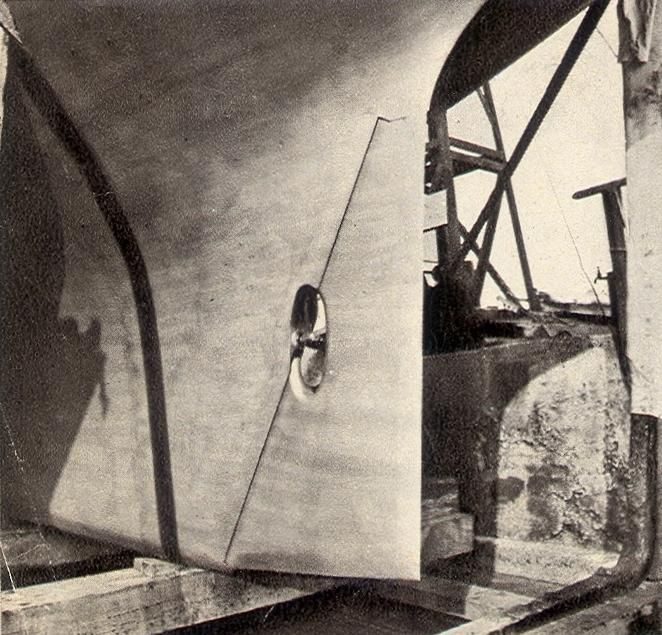

An over-the-shoulder view of Alberg at his drawing table! Can SEE what he's thinking about with the two concepts.

Use those figures as datum for calculating changes....... maybe add a little more area for good measure. Can always grind it off.

I'm thinking more area translates to a harder tiller.

Jerry's invention is very interesting and ORIGINAL (of course!).

And, why not? Let's see what happens, right?

.................................................. .................................................. .................................................. ............................................

*Constellation was a S&S 12meter Rule (39.37ft) America'sCup defender in 1964.

TwelveMeters experienced radical design changes each time they raced, just as the America's Cup challengers today.

The rounded rudder shape morphed into hard edge and hard cornered airfoil and never looked back!

Reply With Quote

Reply With Quote